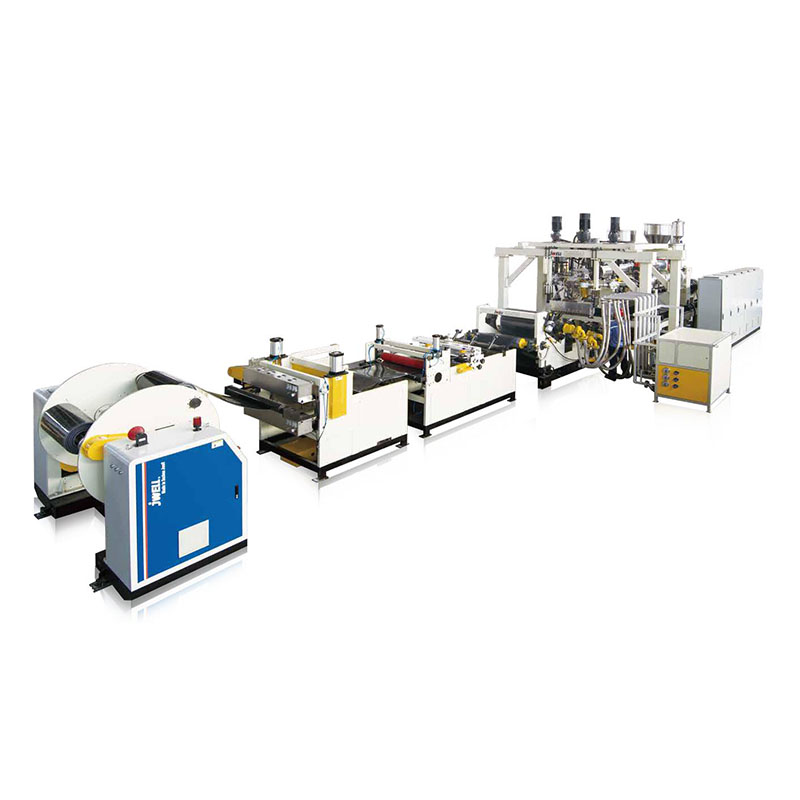

I-PP kanye ne-Calcium Powder Environmental Protection Sheet Extrusion Line

I-PP+CaCo3 i-extrusion ye-extrusion yeshidi yolayini

Ithuthukiswe inkampani ye-Jwell isebenzisa ama-extruder amathathu we-co-extrusion yezendlalelo ezi-3 noma ezi-4. Lo mugqa wamukela isikulufu esiklanywe sakamuva se-Jwell se-PP+CaCo3 kanye nedivaysi elawula ikhompuyutha ye-PLC kanye nedivayisi yokuhlonza ukushuba ngokuzenzakalelayo ukuze umshini ukwazi ukwandisa iphesenti le-CaCo3 ekukhiqizeni amashidi ukuze wehlise izindleko zeshidi kanye neshidi elikhiqizwayo. zuza izakhiwo ezinhle zomzimba kanye namakhono okucubungula okwengeziwe. Iwumshini weshidi othuthuke kakhulu eChina.

Ukucaciswa okuyinhloko kobuchwepheshe

|

Imodeli |

JW-120/100/45-1500 |

|

Ububanzi Bemikhiqizo |

1320 mm |

|

Ukujiya kwemikhiqizo |

0.3mm |

|

Isakhiwo sesendlalelo |

A/B/C/A |

|

Amandla |

800kg/h |

Qaphela: Imininingwane ingashintsha ngaphandle kwesaziso sangaphambili.

Ukuboniswa kwemikhiqizo eqediwe

Ukwakhiwa komshini we-plastic extrusion

Umshini oyinhloko womshini we-plastic extrusion yi-extruder, eyakhiwe uhlelo lwe-extrusion, uhlelo lokudlulisela kanye nesistimu yokushisa nokupholisa.

Isistimu ye-Extrusion

I-extrusion system ihlanganisa i-Extruder, i-Feeding system, i-Screen change, i-Metering pump, i-T-die. Ipulasitiki yenziwe ngepulasitiki ibe incibilike iyunifomu ngohlelo lwe-extrusion, futhi ikhishwa ngokuqhubekayo ngesikulufu ngaphansi kwengcindezi esungulwe kule nqubo.

I-Screw and Barrel: Iyingxenye ebaluleke kakhulu ye-extruder. Ihlobene ngokuqondile nebanga lohlelo lokusebenza kanye nokukhiqiza kwe-extruder. Yenziwe ngamandla aphezulu kanye nensimbi ye-alloy resistant corrosion.I-barrel ibambisana nesikulufu ukuze kuzuzwe ukuchotshozwa, ukuthambisa, ukuncibilika, ukwenza ipulasitiki, ukukhipha umoya kanye nokuhlanganisa ipulasitiki, futhi ngokuqhubekayo nangokufanayo idlulisela irabha ohlelweni lokubumba.

Isistimu yokondla: umsebenzi wayo ukuthutha ngokulinganayo izinhlobo ezahlukene zepulasitiki ku-hopper ye-extruder.

Ukushintsha isikrini: Umsebenzi wawo ukususa zonke izinhlobo zokungcola kupulasitiki

Iphampu yemitha:Ukuhlomisa iphampu phambi kwe-extruder, ukuhlola ingcindezi ngaphambi kwepompo nokulawula isivinini se-extrusion, okunganciphisa ukushayeka kanye nokudla okungajwayelekile futhi kuqinisekise ukuthi i-polymer ikhishwa kahle futhi ihanjiswa ngokuqhubekayo ekhanda lokufa. Igobolondo lepompo lamukela insimbi yensimbi yekhwalithi ephezulu futhi

igiya lisebenzisa insimbi ye-chrome ecinyiwe noma ezinye izinto zensimbi ezisezingeni eliphakeme eziqinisekisa ukusebenza kahle okuphezulu nokuvuza kobufakazi.

I-T-die: Umsebenzi we-T-die ukuguqula inyibiliko yepulasitiki ejikelezayo ibe ukunyakaza okuhambisanayo nomugqa, kwethulwa ngokulinganayo nangokushelelayo.

Isistimu yokudlulisela

Umsebenzi wesistimu yokushayela ukushayela isikulufu futhi unikeze itorque nesivinini esidingwa isikulufu kunqubo ye-extrusion. Ngokuvamile iqukethe injini, i-reducer kanye ne-bearing.

Idivayisi yokushisisa nokupholisa

Ukushisa nokupholisa yizimo ezidingekayo ukuze inqubo ye-plastic extrusion yenzeke.

1. I-extruder ngokuvamile isebenzisa ukushisa kukagesi, okuhlukaniswe ukushisa kokumelana nokushisa kwe-induction. Ishidi lokushisisa lifakwa emzimbeni, entanyeni nasekhanda. Isisetshenziswa sokushisisa sishisisa ipulasitiki kusilinda ngaphandle ukuze kwandiswe izinga lokushisa ukuze kufinyelele izinga lokushisa elidingekayo ekusebenzeni kwenqubo.

2. Idivayisi yokupholisa i-extruder isethwe ukuze kuqinisekiswe ukuthi ipulasitiki isezingeni lokushisa elidingwa inqubo. Ngokukhethekile, okokukhipha ukushisa okudlulele okukhiqizwa ukungqubuzana kwe-shear okubangelwa ukuzungezisa isikulufu, ukuze kugwenywe izinga lokushisa libe phezulu kakhulu ukwenza ipulasitiki ibole, ishe, noma umumo ube nzima. Ukupholisa umgqomo kuhlukaniswe izinhlobo ezimbili: ukupholisa amanzi nokupholisa umoya. Ngokuvamile, ama-extruder amancane naphakathi nendawo afaneleka kakhulu ukupholisa umoya, futhi amakhulu kakhulu apholile ngamanzi noma ahlanganiswe nezinhlobo ezimbili zokupholisa.